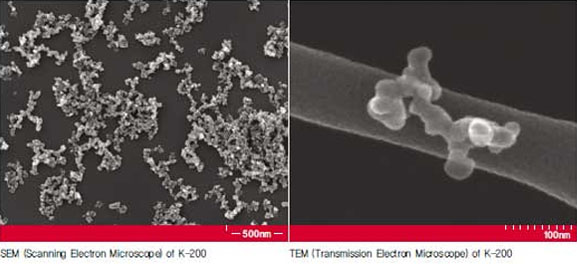

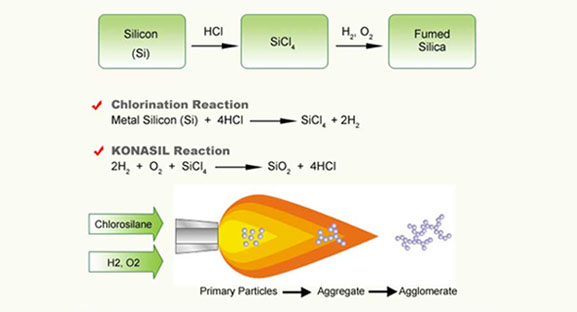

MANUFACTURING PROCESS

|

Unit | Hydrophilic | Hydrophobic³ | Analysis Method | ||||

| K-90 | K-150 | K-200 | K-300 | K-121 | K-122 | |||

| Specific Surface Area | m²/g | 90±15 | 150±20 | 200±25 | 300±30 | 120±20 | 120±20 | B.E.T |

| pH | 3.7 ~ 4.7 | 3.7 ~ 4.7 | 3.7 ~ 4.7 | 3.7 ~ 4.7 | 3.7 ~ 5.5 | 3.7 ~ 5.5 | 4% Dispersion water⁴ | |

| Drying Loss¹ | wt,% | ≤1.0 | ≤1.0 | ≤1.5 | ≤1.5 | ≤0.5 | ≤0.5 | 2 Hours at 105˚c |

| Ignition Loss¹ | wt,% | ≤1.0 | ≤1.0 | ≤1.5 | ≤2.0 | ≤2.0 | ≤2.0 | 2 Hours at 1000˚c |

|

g/l | 50 100 |

50 100 |

50 100 |

50 100 |

50 90 |

50 90 |

|

| 325Mesh Residue | wt,% | <0.05 | <0.05 | <0.05 | <0.05 | |||

| HCI | wt,% | <0.025 | <0.025 | <0.025 | <0.025 | <0.05 | <0.05 | |

| Carbon Contenr | wt,% | 0.6 - 1.2 | 0.6 - 1.2 | |||||

| SiO₂ -Content | wt,% | ≥99.8 | ≥99.8 | ≥99.8 | ≥99.8 | ≥99.8 | ≥99.8 | |

| Al₂O₃² | wt,% | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | |

| Fe₂O₃² | wt,% | <0.003 | <0.003 | <0.003 | <0.003 | <0.01 | <0.01 | |

| TiO₂² | wt,% | <0.03 | <0.03 | <0.03 | <0.03 | <0.03 | <0.03 | |

| Note. | 1) Measure when Fumed silica id produced. |

| 2) Based on ignition at 1000℃ | |

| 3) Under R&D step | |

| 4) 4% dispersion in water : methanol = 1:1 in hydrophobic grade. | |

| The given date are typical values, Specifications on request. |

| 01 CMP slurry abrasive | 06 Unsaturated Polyester Resin (UPR) | 11 Miscellaneous |

| 02 Silicone rubber | 07 Free Flow | |

| 03 Sealants, adhesives and caulks | 08 Heat and electric insulation | |

| 04 Rheology control | 09 Anti-plate-out | |

| 05 Unsaturated polyester gel coats | 10 Anti-blocking and anti-slip |

COPYRIGHT(C) 2008-2015 (주)기수산업. ALL RIGHTS RESERVED.